Abstract: When designing microprocessor cards and memory subsystems cards for backplane-based systems, especially those cards containing data which must be retained during a hot-socket or unexpected power down situation, system designers must consider many issues and their impact on system design. Considerations include: Power monitoring for an orderly switchover to backup memory during power-down and a means to detect a "hot socket" event in time to facilitate the same switchover to backup supplies. This application note addresses these system level issues and discusses some of the devices available from Dallas Semiconductor, which can be used to implement solutions to these design issues.

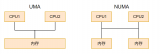

Designing microprocessor cards and memory subsystem cards for backplane-based systems challenges system designers with problems not associated with single motherboard systems. Power supply stabilization, power supply monitoring, backup supply switching, and maintaining memory or microprocessor states when inserting or removing "hot" cards require that the system designer take special care to isolate system memory and microprocessor cards from transient conditions generated by the backplane or by other system cards. Dallas Semiconductor produces three product families, prefabricated memory products, CPU supervisory products, and integrated battery backup products, which are particularly well suited for subsystem card designs.

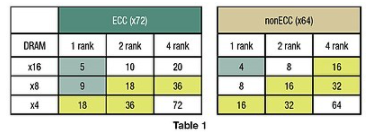

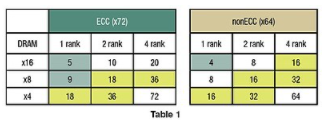

As an example let's say that you need to design a memory subsystem with the following minimum requirements:

Each of these system functions can be realized using a condensed, off-the-shelf Dallas Semiconductor solution. Let's begin with the memory requirements.

In order to provide a low-voltage, backup-compatible memory, without the need for refresh circuitry, the best choice is to use SRAM memory. The 85 ns memory access requirement is available in SRAM as well. What we also need, however, is a way to provide system users with a convenient way of adding memory as they need it. Most likely, the end user does not want to have to add the memory SRAM by SRAM, or fumble with the individual parts themselves. Dallas Semiconductor's solution to this requirement is the DS2229. The DS2229 512K x 16-bit prefabricated memory Stik conforms to the JEDEC 80-pin connection standard. The high density word-wide configuration of the prefabricated memory Stik provides the memory card with more memory per surface area than surface-mounting the individual SRAMs directly onto the memory card. The modularity of a DS2229 makes it possible to provide the memory card's user with maximum flexibility in adding additional memory over the 2M x 16 minimum requirement. Four DS2229's satisfy the minimum requirement, with 80-pin JEDEC sockets on the card for up to four more DS2229's. Since the DS2229's are also removeable from the memory card, the card can be reconfigured as necessary, or DS2229's from one card can be used to upgrade the memory in other cards, or to provide base memory for other cards, reducing the overall cost of implementation for such a flexible memory subsystem.

512K X 16 80-Pin JEDEC Standard SIP Stik

512K X 16 80-Pin JEDEC Standard SIP Stik

With items 1, 2, and 3 of the system requirements met, the next functions that can be easily consolidated into a one-chip solution are the power switching functions. The DS1336 is ideally suited for our system requirements (see Figure 2). The device can switch between a 3V or 5V, 1.5A supply to a backup 3V supply, with a maximum backup current of 4 mA. The DS1336 requires an external notification of a power failure. Once the external input is activated, the DS1336 immediately switches from the primary power supply to the backup power supply, in this case a lithium power source. Since the DS1336 has two complemented power-fail inputs, Active-low PF and PF , one can be used for the on-card power monitor, and the other can be connected to a power-fail status indicator on the backplane which can provide an advanced warning of a power failure, before it reaches the memory card.

What about the primary and backup power supply management requirements? Again, Dallas Semiconductor offers several condensed solutions which are user-configurable to meet diverse system requirements. Let's begin with the power monitoring requirements.

If we want to monitor the status of our on-board power supply, backup supply, and also monitor the external connections to the backplane, we need to be able to monitor all of these supplies, and be able to use the output signals to drive high current switching circuitry. Dallas Semiconductor offers the DS1236 MicroManager, which condenses all of the required functions into one chip.

Figure 1. DS1236 MicroManager.

The DS1236 MicroManager monitors the primary power supply VCC from the backplane, and the backup lithium source. If VCC falls out of tolerance, the DS1236 provides two complemented power-fail signal outputs, PF and PF, either of which can be used to signal to a DS1336 to switch power from the primary supply to the backup lithium energy source. The DS1236 also has a user-definable voltage monitor, which in our memory card implementation can be used to monitor the status of the backup lithium source. In the implementation shown below, if the backup lithium source's voltage falls below 2.54V, the DS1236 will assert its /NMI\ output to warn the memory controller or microprocessor that the backup power supply has failed. This feature satisfies requirement 9.

Figure 2. DS1336 Afterburner 16-Pin DIP or SOIC.

The last system requirement, that of write protecting memory, is accomplished by controlling the chip enable lines to the DS2229 prefabricated memory sticks. The chip enable input from the memory controller is fed to the DS1236, and is passed out as CEO during normal VCC operating conditions. During an out-of-tolerance condition, the DS1236 holds CEO high so that a write to the memory with corrupted data can be prevented.

With the primary power supply monitoring requirements satisfied, we still require a method to switch from the higher active currents of the DS2229's to the very low data retention currents required for maintaining the memory in a standby state. The active current required for the system is:

8 × (DS2229 ICC0) = 8 × 100 mA = 800 mA maximum

The data retention current required for the system is:

8 × (DS2229 ICC or standby) = 8 × 8 μA = 64 μA

The power requirements for maintaining the memory contents in the absence of power is then:

2 years × 64 μA = 128 μA-years or 1122 mAh, so a minimum of a 1.2 Amp-Hour lithium source will be required.

To switch between the high current and low current requirements of the memory requires the ability to switch between the 5V high current supply and 3V backup supply, without dropping the current supply to the memory below the minimum required to keep it active. The DS1336 consolidates the required switching functions into a single 16-pin SOIC device capable of switching even more current than we require, up to 1.5A of active current. The DS1336 contains a series of five power FETS which can each handle 300 mA, for a combined capacity of 1.5A.

VCC from the primary power supply is tied to the five IN pins of the DS1336, with the five OUT pins tied together and to the VBAT01 pin. The VBAT01 pin of the DS1336 has a series diode to prevent VCC from charging the backup lithium supply, which is connected to VBATIN. When PF becomes active from the DS1236, indicating a primary power failure on the memory card, the DS1336 switches power from the primary supply to the secondary lithium supply within 100 ns. In order to monitor power supplied by the backplane, the DS1336's other power fail input, Active-low PF, can be connected to a Active-low PF signal on the backplane, so that a backplane failure can also cause the DS1336 to switch to the backup power source.

For Larger Image

For more information on high density nonvolatile memory applications and related subsystems, please call the Dallas Semiconductor factory at (214) 450-0448.

Designing microprocessor cards and memory subsystem cards for backplane-based systems challenges system designers with problems not associated with single motherboard systems. Power supply stabilization, power supply monitoring, backup supply switching, and maintaining memory or microprocessor states when inserting or removing "hot" cards require that the system designer take special care to isolate system memory and microprocessor cards from transient conditions generated by the backplane or by other system cards. Dallas Semiconductor produces three product families, prefabricated memory products, CPU supervisory products, and integrated battery backup products, which are particularly well suited for subsystem card designs.

As an example let's say that you need to design a memory subsystem with the following minimum requirements:

- Board must have single-sided assembly.

- 2M x 16 of base memory required, with capabilities to support up to an additional 2M x 16 of extended memory, for a total of 4M x 16. Access times of 85 ns are required.

- Memory must require no stand-alone refresh circuitry.

- A backup power supply must be available to maintain the contents of the base memory and extended memory on the card.

- Power supply (5V) must be monitored both on the subsystem card as well as on the backplane card.

- Switching from VCC to the secondary power supply must be automatically executed during a power- down or power failure.

- Switching from the backup power supply to VCC on power up must automatically occur once VCC is in tolerance.

- Switching system must be able to switch during a "hot card" situation without losing the contents of memory, requiring a smooth transition from a high current active memory state to a low current backup state.

- The backup power supply must provide an advance warning of an impending out-of-tolerance condition on the backup supply.

- Memory must be write protected during a power failure to prevent it from becoming corrupted.

Each of these system functions can be realized using a condensed, off-the-shelf Dallas Semiconductor solution. Let's begin with the memory requirements.

In order to provide a low-voltage, backup-compatible memory, without the need for refresh circuitry, the best choice is to use SRAM memory. The 85 ns memory access requirement is available in SRAM as well. What we also need, however, is a way to provide system users with a convenient way of adding memory as they need it. Most likely, the end user does not want to have to add the memory SRAM by SRAM, or fumble with the individual parts themselves. Dallas Semiconductor's solution to this requirement is the DS2229. The DS2229 512K x 16-bit prefabricated memory Stik conforms to the JEDEC 80-pin connection standard. The high density word-wide configuration of the prefabricated memory Stik provides the memory card with more memory per surface area than surface-mounting the individual SRAMs directly onto the memory card. The modularity of a DS2229 makes it possible to provide the memory card's user with maximum flexibility in adding additional memory over the 2M x 16 minimum requirement. Four DS2229's satisfy the minimum requirement, with 80-pin JEDEC sockets on the card for up to four more DS2229's. Since the DS2229's are also removeable from the memory card, the card can be reconfigured as necessary, or DS2229's from one card can be used to upgrade the memory in other cards, or to provide base memory for other cards, reducing the overall cost of implementation for such a flexible memory subsystem.

512K X 16 80-Pin JEDEC Standard SIP Stik

512K X 16 80-Pin JEDEC Standard SIP StikWith items 1, 2, and 3 of the system requirements met, the next functions that can be easily consolidated into a one-chip solution are the power switching functions. The DS1336 is ideally suited for our system requirements (see Figure 2). The device can switch between a 3V or 5V, 1.5A supply to a backup 3V supply, with a maximum backup current of 4 mA. The DS1336 requires an external notification of a power failure. Once the external input is activated, the DS1336 immediately switches from the primary power supply to the backup power supply, in this case a lithium power source. Since the DS1336 has two complemented power-fail inputs, Active-low PF and PF , one can be used for the on-card power monitor, and the other can be connected to a power-fail status indicator on the backplane which can provide an advanced warning of a power failure, before it reaches the memory card.

What about the primary and backup power supply management requirements? Again, Dallas Semiconductor offers several condensed solutions which are user-configurable to meet diverse system requirements. Let's begin with the power monitoring requirements.

If we want to monitor the status of our on-board power supply, backup supply, and also monitor the external connections to the backplane, we need to be able to monitor all of these supplies, and be able to use the output signals to drive high current switching circuitry. Dallas Semiconductor offers the DS1236 MicroManager, which condenses all of the required functions into one chip.

Figure 1. DS1236 MicroManager.

The DS1236 MicroManager monitors the primary power supply VCC from the backplane, and the backup lithium source. If VCC falls out of tolerance, the DS1236 provides two complemented power-fail signal outputs, PF and PF, either of which can be used to signal to a DS1336 to switch power from the primary supply to the backup lithium energy source. The DS1236 also has a user-definable voltage monitor, which in our memory card implementation can be used to monitor the status of the backup lithium source. In the implementation shown below, if the backup lithium source's voltage falls below 2.54V, the DS1236 will assert its /NMI\ output to warn the memory controller or microprocessor that the backup power supply has failed. This feature satisfies requirement 9.

Figure 2. DS1336 Afterburner 16-Pin DIP or SOIC.

The last system requirement, that of write protecting memory, is accomplished by controlling the chip enable lines to the DS2229 prefabricated memory sticks. The chip enable input from the memory controller is fed to the DS1236, and is passed out as CEO during normal VCC operating conditions. During an out-of-tolerance condition, the DS1236 holds CEO high so that a write to the memory with corrupted data can be prevented.

With the primary power supply monitoring requirements satisfied, we still require a method to switch from the higher active currents of the DS2229's to the very low data retention currents required for maintaining the memory in a standby state. The active current required for the system is:

8 × (DS2229 ICC0) = 8 × 100 mA = 800 mA maximum

The data retention current required for the system is:

8 × (DS2229 ICC or standby) = 8 × 8 μA = 64 μA

The power requirements for maintaining the memory contents in the absence of power is then:

2 years × 64 μA = 128 μA-years or 1122 mAh, so a minimum of a 1.2 Amp-Hour lithium source will be required.

To switch between the high current and low current requirements of the memory requires the ability to switch between the 5V high current supply and 3V backup supply, without dropping the current supply to the memory below the minimum required to keep it active. The DS1336 consolidates the required switching functions into a single 16-pin SOIC device capable of switching even more current than we require, up to 1.5A of active current. The DS1336 contains a series of five power FETS which can each handle 300 mA, for a combined capacity of 1.5A.

VCC from the primary power supply is tied to the five IN pins of the DS1336, with the five OUT pins tied together and to the VBAT01 pin. The VBAT01 pin of the DS1336 has a series diode to prevent VCC from charging the backup lithium supply, which is connected to VBATIN. When PF becomes active from the DS1236, indicating a primary power failure on the memory card, the DS1336 switches power from the primary supply to the secondary lithium supply within 100 ns. In order to monitor power supplied by the backplane, the DS1336's other power fail input, Active-low PF, can be connected to a Active-low PF signal on the backplane, so that a backplane failure can also cause the DS1336 to switch to the backup power source.

For Larger Image

For more information on high density nonvolatile memory applications and related subsystems, please call the Dallas Semiconductor factory at (214) 450-0448.

電子發(fā)燒友App

電子發(fā)燒友App

評論