摘要

基于ADAS (高級駕駛輔助系統(tǒng))系統(tǒng)中77/79GHz汽車防撞雷達的潛在增長。從電氣和可靠性的角度來看,無玻纖的聚四氟乙烯陶瓷板材相較于非聚四氟乙烯的板材具有明顯的優(yōu)勢。

聚四氟乙烯(PTFE)的介電常數(shù)和損耗因子在傳感器諧振頻率要求的工作溫度范圍內表現(xiàn)出高穩(wěn)定性,幾十年來得到了射頻和微波行業(yè)的廣泛認可。

聚四氟乙烯基材上搭配極低粗糙度(ULP,Ultra Low Profile)的電解銅箔,相較于壓延銅箔,其插損更低,成本也更有競爭力。

圖1:ADAS的應用

ADAS案例

為什么現(xiàn)在我們都對ADAS系統(tǒng)中的77/79GHz汽車防撞雷達產品如此感興趣呢?盡管前期數(shù)量不多,但市場的可接受度正變得越來越高,就像很多年前的ABS系統(tǒng)一樣,從開始只有豪華車配置到后來的所有車輛配置,可預見未來幾年其將呈指數(shù)級增長,因為所有的汽車制造商都希望引入ADAS系統(tǒng)。

圖2:77GHz 防撞雷達(博世提供)

圖3:77GHz 防撞雷達(博世提供)

材料特性

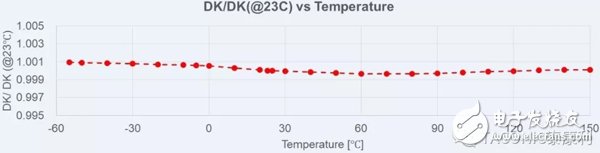

PCB中使用的射頻板材必須在非常寬的溫度范圍內保持非常穩(wěn)定的電氣性能。PTFE板材顯示出非常穩(wěn)定的DK / DK(@23C)比值,溫度由-50到+ 150°C(圖4):

圖4:PTFE板材從-50到+150 °C表現(xiàn)出非常穩(wěn)定的Dk特性

同樣的,Df在同樣的溫度范圍內的變化非常平緩(圖5):

圖5:PTFE板材從-50 到+150 °C的Df

而非聚四氟乙烯(Non-PTFE)樹脂有著較高的極性,碳-氧鍵(C-O)容易被極化,其表現(xiàn)為在高頻應用時電氣性能不穩(wěn)定。

NF-30是一款不含玻纖的聚四氟乙烯板材,其在X,Y,Z三個方向上的各向一致性非常好。從電氣性能上考量,常規(guī)玻璃纖維布的存在會導致板材在各向之間的差異。當然扁平玻璃布會較常規(guī)玻璃布有一定改善,但也不能完全消除這個差異。

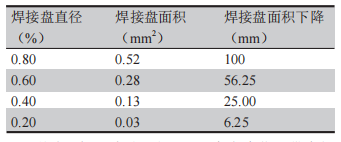

“極低粗糙度”電解銅箔(ULP)與傳統(tǒng)的低粗糙度電解銅箔(VLP)相比(圖6),ULP銅箔能夠做出更精細的圖形和更嚴的線寬公差。

圖6: ULPH銅箔與VLP銅箔的對比(盧森堡銅箔提供)

更重要的是,插損得到了極大的改善,頻率越高越明顯(圖7.):

圖7:NF-30 Hoz銅箔的極低粗糙度(ULPH),反轉銅(CLH)與低粗糙度(CH)的插損對比

圖8:1OZ銅箔的極低粗糙度(ULPH),壓延(RA)與低粗糙度(HVLP)搭配相同的介質材料,測試至110GHz的插損對比

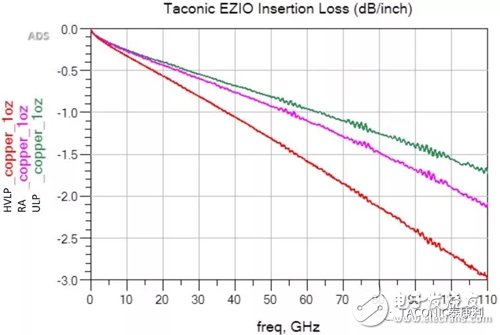

1oz的極低粗糙度電解銅(ULP)、壓延銅(RA)、低粗糙度電解銅(HVLP)插損的對比。頻率測至110GHz時,ULP與RA銅相比,優(yōu)勢越來越大(圖8).

此外,PTFE板材的另一個主要優(yōu)點在于無論采用何種表面處理方式,其銅箔附著力在多次無鉛回流后,仍然能夠保持較高的水平。ULP剝離強度的測試結果與HVLP幾乎一樣(圖9).

圖9:Hoz極低粗糙度(ULPH)的銅箔經過3次與5次IR-Reflow后的剝離強度

DK,插損的測量

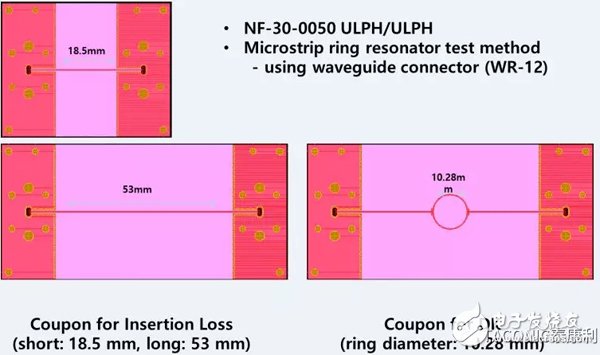

再好的理論數(shù)據(jù),不如在77GHz測量實際的DK和插損。DK測量采用波導連接器諧振環(huán)測試方法測量微帶線,而插損測量采用不同長度的微帶線。(圖10).

圖10:Dk與插損的微帶線諧振環(huán)測試圖形

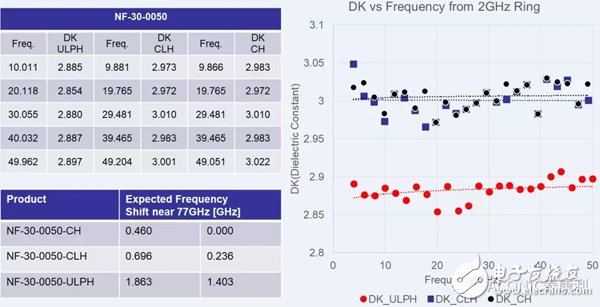

在77GHz測試頻率下,ULP銅箔改善了插損,但是DK比普通銅箔在77GHz時的理論值低了大約0.1 (圖11).

圖11:NF-30 Dk隨頻率的偏移與銅箔類型有關

這種影響是由于這種銅箔的類型導致的,但很容易在仿真軟件里進行調整。

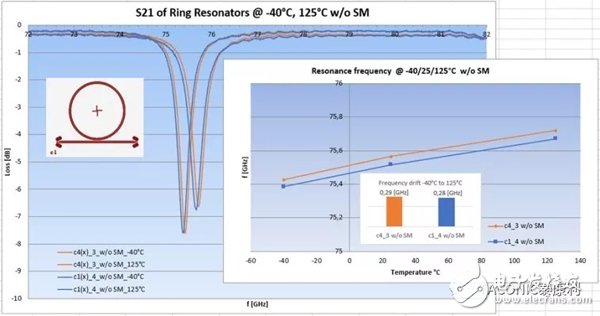

諧振環(huán)S21在-40°C 和+125°C測量表現(xiàn)了這一點偏移(圖12):

圖12:S21諧振環(huán)測量的在-40°C和+125°C偏移(博世提供)

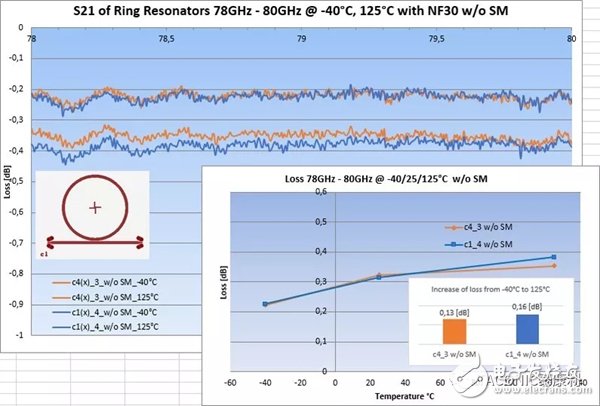

同時諧振環(huán)在78~80GHz的插入損耗也是可以接受的(圖13):

圖13:S21諧振環(huán)在-40°C 和+125°C測量的插損(博世提供)

大多數(shù)的77/79 GHz ADAS 線路板是多層混壓板, 只有第1層到第2層是PTFE板材.

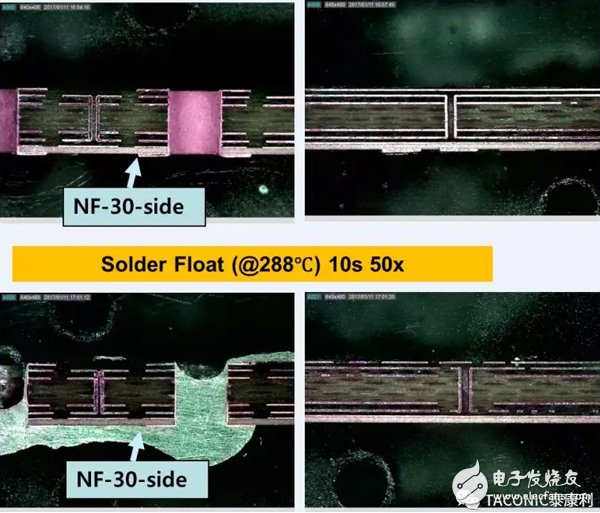

PTFE板材的高可靠性在以下的288 °C的漂錫測試中得到驗證(圖14 a-c):

圖14a: NF-30 288°C漂錫前

圖14b: NF-30 在做288 °C漂錫

圖14c: NF-30 288 °C漂錫30分鐘后: 沒有起泡,沒有爆板!

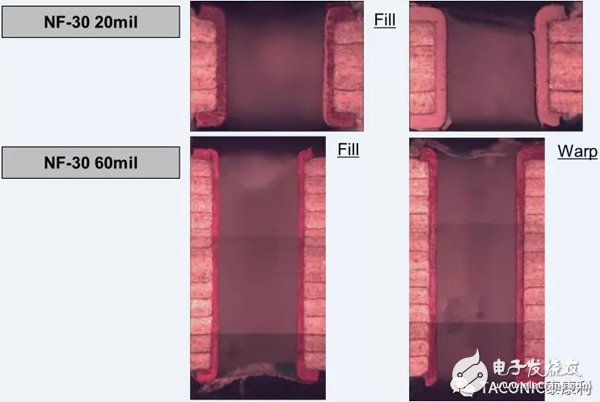

使用較厚的厚度20和60mil的NF-30來測試鉆孔,除孔污和電鍍孔,很明顯這種無玻纖PTFE板材PTH孔孔壁質量非常高(圖15)

圖15: 20mil與60mil NF-30的PTH孔

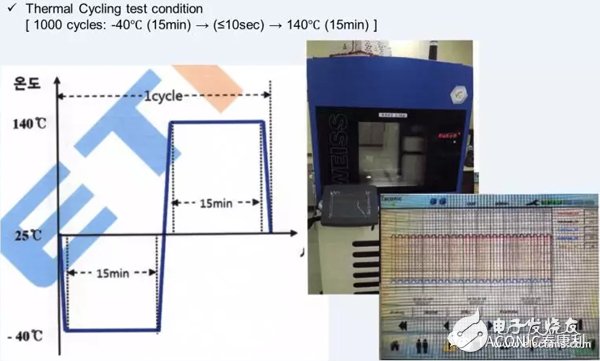

1000次-40°C到+ 140°C冷熱沖擊循環(huán)是對混壓多層板來說是極大的挑戰(zhàn)(圖16, 17)

圖16: 混壓多層板的冷熱循環(huán)曲線 -40°C到+ 140°C 1,000循環(huán)

不管怎樣,1000次循環(huán)測試后沒有任何問題。

圖17:NF-30混壓多層板切片 –NF-30的多層板及盲孔;熱循環(huán)前與熱循環(huán)后

即使經過50次的漂錫試驗(288 °C,10S),依然顯示出很高的可靠性(圖18)

圖18:NF-30的混壓多層板經過50次漂錫( 288 °C 10秒)

高可靠性和電氣性能需要從板材的生產過程到場景應用一直保持著穩(wěn)定的介電常數(shù)。一個眾所周知的顧慮就是陶瓷填料板在PCB制作過程中的藥水吸附問題。NF-30采用更好的配方來減少最常見的化學藥水的滲透問題。 圖19顯示了NF-30與市場的另一款無玻纖結構PTFE介質材料的耐化學藥水吸附測試結果。

圖19:NF-30與其他材料相比,明顯減少化學藥水的吸收

結論

NF-30 是一款高可靠性射頻材料,適用于77/79GHz 汽車防撞雷達的混壓多層板, 純多層板以及雙面板的設計。

參考文獻

除了一些特定的引用外,其他所有信息都是Taconic內部測試信息。

———————————————————

附英語原文:

FOR 77/79 GHZ SAFETY AND RELIABILITY APPLICATIONS THE MOST RELIABLE LAMINATES ARE USED

Manfred Huschka1

1Taconic Advanced Dielectric Division,Mullingar, Ireland

Keywords: ADAS, PTFE, NON-REINFORCED,COPPER FOIL, INSERTION LOSS

Abstract

Due to the expected potential growth of 77/79 GHz ADAS (Advanced Ariver-Assistance System) several non-PTFE (Polytetra Fluoro Ethylene) laminates are trying to find their way into designs. However from electrical and mechanical reliability points of view non-reinforced PTFE/Ceramic laminates still provide a leading edge.

The high consistency of dielectric constant and loss factor of the thermoplastic material PTFE over the required operating temperature range at resonance frequency of the sensors has been recognized by the RF and microwave industry since tens of years. This is also one of the main reasons why such types of laminates are being used for every ADAS generation up to now.

For many years only one kind of such laminate was available and therefore is widely used in the industry. 2017 saw the emergence of another such type of laminate, whose tested reliability data confirm that the selection of non-reinforced PTFE laminates for 77/79 GHz is the correct one. In fact, certain features demonstrate a second generation laminate is needed in order to meet the requirements of next generation 77/79 GHz ADAS.

The market introduction of almost no profile ED (Electro-Deposited) copper foil provides an even improved insertion loss over rolled annealed copper foil, in addition to its lower cost. Only PTFE laminates result in high enough copper peel strength even at repeated rework cycles.

The Case for ADAS

Why are we now so interested in 77 GHz ADAS? It has been around for some time, although in small volumes. The market acceptance is becoming quite high, and in a similar way as ABS years ago it gets cascaded down from luxury cars to almost every car. Exponential growth rates in the next few years are expected – and will happen, because all the car makers want to introduce ADAS.

Safety and reliability have become key words in the industry.

BaseMaterial Characteristics

The RF laminate used in the printedcircuit board is required to be very stable over a very wide temperature range.PTFE laminates show a very tight DK/DK(@23C) (Dielectric Constant/Loss Factor) behaviourfrom -50 to +150 °C (Fig. 4):

Likewise the gradient of DF over the same temperature range is very low (Fig. 5):

Non-PTFE organic resins are bound to have higher levels of natural electrical polarity - the Carbon-Fluorine bond in PTFE is short and not very polarizable in an electrical field, while Carbon-Oxygen bonds are naturally more polarizable. This means a lesser degree of stability over frequency.

NF-30 is a non-reinforced PTFE laminate, just containing ceramic fillers. Same as the laminate being used for current 77 GHz designs, it is electrically very homogeneous in all 3 directions. A woven fiberglass reinforced resin will naturally have some electrical anisotropy due to the fiberglass weave structure, which in particular high mmWave frequencies are sensitive to. It is possible to flatten the fiberglass however the warp yarns never get flat. There will always be a higher level of anisotropy in these type of resin systems.

Recent developments in copper foil technology have resulted in the introduction of a so-called “Almost No Profile” ED copper foil [Taconic grade name for Hoz is ULPH] (Fig. 6). Compared with a traditional Very Low Profile copper foil this foil leads to better defined and much steeper sidewalls of traces due to less copper treatment which has to get etched out of the substrate; in other words, finer features with tighter tolerances are possible.

And what’s of significance is that the insertion loss gets improved considerably – the higher the frequency the better the insertion loss (Fig 7.):

Insertion Loss Comparison of 1 oz “Almost No Profile” ED copper foil (ULP), Rolled Annealed copper foil (RA), and Flat Profile ED copper foil (HVLP) on a different substrate, measured up to 110 GHz shows that the improvement gap widens even more compared with RA copper foil (Fig. 8).

A major advantage of a thermoplastic substrate, such as PTFE, lies in the high copper foil peel strength even after repeated IR reflows, irrespective whether an organic surface protection (PSR) is used or just immersion tin. Measured peel strength values are in the same range as of standard Very Low Profile copper foil (Fig. 9).

mmWave Measurements

All theory is fine, however the proof isin the pudding when doing actual DK and Insertion Loss tests at 77 GHz.Microstrip ring resonator test method using waveguide connectors is applied forDK measurements, whereas strip lines of different lengths are used forInsertion Loss (Fig. 10).

Although the Almost No Profile copper foil improves the insertion loss, it also leads to a DK shift to a 0.1 lower value for design purposes at 77 GHz (Fig. 11).

This observed effect is due to the actual profile structure of this copper foil, and can easily be incorporated into any design through simulation software.

S21 of ring resonators measured at -40°C and at +125°C show a quite small frequency drift (Fig. 12):

Also the observed loss in the frequency range between 78 and 80 GHz shows an acceptable increase (Fig. 13):

Most 77/79 GHz ADAS pcbs are hybrid multilayer pcbs, where only layers 1 and 2 are PTFE laminate.

Aforementioned high reliability of PTFE laminates can easily get demonstrated during 288 °C solder float (Fig. 14 a-c):

Taking the unusual step of using rather thick 20 and 60 mil NF-30 to demonstrate via drilling, hole wall desmearing and pth, it is obvious that it is of no issue for this no glass containing PTFE laminate (Fig. 15)

The biggest challenge is thermal cycling of the hybrid multilayer - 1,000 cycles from -40°C to + 140°C (Fig. 16, 17)

Howeverthe hybrid multilayer survives this test without any issues:

And even after 50x solder float (10 s at 288 °C) the hybrid multilayer shows its superior quality (Fig.18)

Reliability and electrical performance needs dielectric consistency from laminate production through to field deployment. A known concern with ceramic filled dielectrics is process chemistry absorption during the PCB fabrication steps. Observations in one popular laminate of cosmetic changes, as well as some measured shifts in electrical properties at 77/79GHz. It is much preferred to have finished PCBs with no contamination and NF-30 is constructed to minimize penetration and interaction of most common PCB chemistry. Fig 19 shows tests of machined NF-30 dielectric. This is achieved through care in ceramic filler selection and mixing, leading to better cosmetic results after etching in the PCB production process.

Conclusion

NF-30 is truly a high reliability RF basematerial, suitable for 77/79 GHz ASAS hybrid multilayer printed circuit boards,all-RF multilayer printed circuit boards, as well as double-sided printedcircuit boards. The combination of non-reinforced PTFE laminates with Almost NoProfile copper foil is the ideal solution – providing the supply chain with asafe knowledge of long term reliability in operation.

References

Except wherespecific references were made all other information is Taconic internal test information.

Biography

Dipl.-Ing. Manfred Huschka spent his entire professional career in the printed circuit board industry: After graduation he was manufacturing printed circuit boards (Braun Ireland Ltd). Thereafter manufacturing FR4 base materials (AlliedSignal Laminate Systems), with his final position being Director Technology Europe. Since 1997 Manfred is with Taconic, manufacturing PTFE base materials. In those more than 20 years he was in charge of the Irish manufacturing plant for more than 10 years, and is Vice President Global Sales.

-

PTFE

+關注

關注

0文章

51瀏覽量

13151 -

adas

+關注

關注

309文章

2184瀏覽量

208634

發(fā)布評論請先 登錄

相關推薦

PCB高可靠性化要求與發(fā)展——PCB高可靠性的影響因素(上)

基于TI電感傳感技術的高可靠性低成本金屬按鍵設計

中微代理 CMS79FT738 高可靠性、易過CS測試 用于家用電器產品

干簧開關與傳感技術:無功耗與高可靠性的完美結合

AWR1642單芯片77GHz和79GHz FMCW雷達傳感器數(shù)據(jù)表

AWR1243單芯片77GHz和79GHz FMCW收發(fā)器數(shù)據(jù)表

AWR1443單芯片77GHz和79GHz FMCW雷達傳感器數(shù)據(jù)表

AWR1843 單芯片 77GHz 至 79GHz FMCW 雷達傳感器數(shù)據(jù)表

汽車功能安全與可靠性的關系

紅外探測器封裝秘籍:高可靠性鍵合工藝全解析

太陽誘電高可靠性元件工業(yè)設備用途

應用于77/79 GHz汽車防撞雷達的高可靠性板材

應用于77/79 GHz汽車防撞雷達的高可靠性板材

評論