1 背景

在2021年接觸到步進(jìn)電機(jī),當(dāng)時(shí)是用來(lái)驅(qū)動(dòng)熱敏打印機(jī),沒(méi)有用到加減速算法,速度時(shí)間表好像是日本客戶那邊提供過(guò)來(lái)的,這次調(diào)試加減速算法,遇到了不少問(wèn)題,在這里記錄一下,希望能幫到未來(lái)對(duì)此有困惑的自己,如果能幫到其他人也算是有幸。

2 步進(jìn)電機(jī)基本參數(shù)

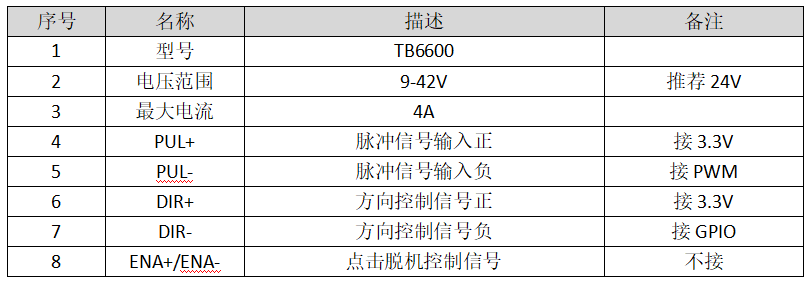

2.1 驅(qū)動(dòng)器

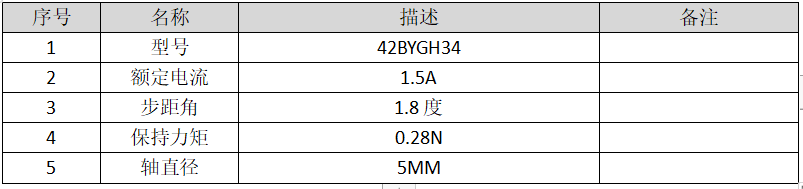

2.2 電機(jī)

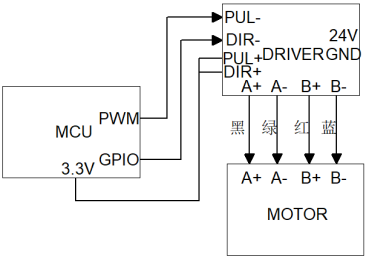

2.3 接線

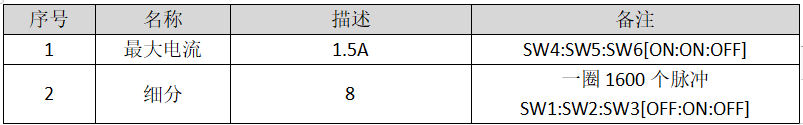

2.4 細(xì)分及電流配置

2.5 驅(qū)動(dòng)方式

一般有3種:定時(shí)器中斷+GPIO、GPIO+延時(shí)、PWM比較輸出,這里使用的是PWM比較輸出模式,在比較中斷中不斷地更新PWM周期來(lái)達(dá)到改變速度的目的。

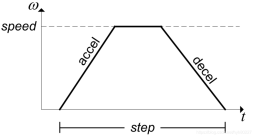

3 梯形加減速算法

3.1 推導(dǎo)過(guò)程

3.1.1 組成部分

步進(jìn)電機(jī)的動(dòng)作過(guò)程是由加速、勻速、減速三個(gè)部分組成,轉(zhuǎn)速的單位是rpm,每分鐘多少轉(zhuǎn),最終需要rpm轉(zhuǎn)換成每秒的脈沖數(shù)也就是頻率,速度越快頻率越大,對(duì)應(yīng)的脈沖周期T就越小。

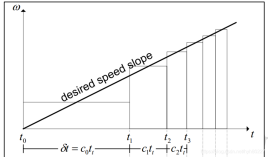

3.1.2 速度和脈沖周期的關(guān)系

第1個(gè)脈沖周期t=t1-t0,第2個(gè)脈沖周期t=t2-t1,那么t=計(jì)數(shù)值*計(jì)數(shù)時(shí)間,例如72MHz的情況下,定時(shí)器預(yù)分配為72-1,計(jì)數(shù)值設(shè)置為0xFFFF,脈沖周期t=65535*(1/1MHz),使用PWM的翻轉(zhuǎn)模式,翻轉(zhuǎn)模式下,2次翻轉(zhuǎn)為一個(gè)完整脈沖,那么設(shè)置比較值為0xFFFF/2,那么t=65.535ms,速度pps=15.2Hz,也就是1秒鐘15.2個(gè)脈沖。

3.1.3 加速度和距離的關(guān)系

s=vot + (1/2)at2,由于初速度為0,那么S=(1/2)*a*t2

s=alpha(步距角)*n(脈沖數(shù)),那么(1/2)at2=alpha*n

整個(gè)加速時(shí)間t=tn-t0,t0=0,那么tn=t,那么tn=√(2*n *alpha/a)

tn=cn*tt(計(jì)數(shù)時(shí)間)

3.1.4 下一個(gè)脈沖計(jì)數(shù)

cn*tt=t(n+1)-tn=√(2*(n-1) *alpha/a)-√(2*(n) *alpha/a)

cn=1/tt (√(n+1)-√n)√(2*alpha/a)

c0=1/tt √(2alpha/a)

cn=c0*(√(n+1)-√n)

根據(jù)麥克勞林公式

√(n+-1) = 1+-1/2n-1/8*n2+O(1/n3)

cn/cn-1 = c0(√(n+1)-√n)/c0(√(n)-√n-n)

最終化簡(jiǎn)后得到

cn=cn-1 - (2cn-1 / 4n+1)

3.1.5 誤差和放大倍數(shù)

當(dāng)n=1時(shí)有0.4485的偏差,將C0乘以0.676來(lái)解決這個(gè)誤差

假設(shè)主頻為72M預(yù)分頻系數(shù)為72-1,那么

C0 = 10000000.676√(2alpha/a)

為了保證計(jì)算的精度,需要對(duì)相關(guān)變量進(jìn)行放大處理,這里對(duì)加速度放大10倍

C0=10000000.676 √(2alpha/a10)

那么對(duì)2*alpha乘以100000,

根號(hào)中2alpha100000/a10=2alpha*10000/a

100*√(2*alpha/a)

對(duì)1000000*0.676除以10倍,然后再對(duì)整個(gè)結(jié)果除以10,那么

C0=(10000000.676 /10√(2*alpha/a))/10

3.1.6 相關(guān)宏定義

#define FSPR 200

#define MICRO_STEP 8

#define SPR (FSPR*MICRO_STEP)

#define ALPHA 2*3.14159/SPR

#define GAIN_X 10

#define FREQUENCY_1 1000000*0.676/GAIN_X

#define ALPHA_2_GAIN_100000 2ALPHA100000

3.2 單位轉(zhuǎn)換

通常情況下加減速時(shí)間(ms)、最大速度(mm/s)、距離(mm)是已知的,我們需要將轉(zhuǎn)速mm/s轉(zhuǎn)換成角速度(rad/s),將加減速時(shí)間轉(zhuǎn)換成加速度(rad/sec^2)

已知公式角速度=轉(zhuǎn)速*2π/60

假設(shè)轉(zhuǎn)速有9.55rpm,那么角速度=9.5523.14159/60=1(rad/s)

3.2.1 單位轉(zhuǎn)換相關(guān)宏定義

假設(shè)軸直徑是5mm,默認(rèn)情況下1轉(zhuǎn)的距離是(5*3.1415)

#define CONFIG_ROUND_MM (5*3.1415)

#define MMPS_TO_RPM(SPEED) (SPEED*60/CONFIG_ROUND_MM)

#define RPM_TO_RADPS(SPEED) (SPEED*2π/60)

#define MMPS_TO_RAD_PS(SPEED) (SPEED*2π/CONFIG_ROUND_MM)

#define MMPS_TO_RAD_0_1_PS(SPEED) (SPEED102π/CONFIG_ROUND_MM)

3.3 代碼部分

3.3.1 初始化

PA1作為PWM,PA2作為DIR

TIM_HandleTypeDef htim2;

void TIM_PWM_Init(u16 arr,u16 psc)

{

TIM_OC_InitTypeDef sConfigOC = {0};

htim2.Instance = TIM2;

htim2.Init.Prescaler = psc;

htim2.Init.CounterMode = TIM_COUNTERMODE_UP;

htim2.Init.Period = arr;

htim2.Init.ClockDivision = TIM_CLOCKDIVISION_DIV1;

htim2.Init.AutoReloadPreload = TIM_AUTORELOAD_PRELOAD_DISABLE;

htim2.Init.RepetitionCounter = 0;

HAL_TIM_OC_Init(&htim2);

sConfigOC.OCMode = TIM_OCMODE_TOGGLE;;

sConfigOC.Pulse = arr/2;

sConfigOC.OCPolarity = TIM_OCPOLARITY_HIGH;

sConfigOC.OCFastMode = TIM_OCFAST_DISABLE;

HAL_TIM_OC_ConfigChannel(&htim2, &sConfigOC, TIM_CHANNEL_2);

HAL_TIM_Base_Start(&htim2);

}

void HAL_TIM_OC_MspInit(TIM_HandleTypeDef *htim)

{

if (htim->Instance == TIM2)

{

GPIO_InitTypeDef GPIO_Initure;

__HAL_RCC_TIM2_CLK_ENABLE();

__HAL_AFIO_REMAP_TIM2_PARTIAL_2();

__HAL_RCC_GPIOA_CLK_ENABLE();

GPIO_Initure.Pin=GPIO_PIN_1; //PB5

GPIO_Initure.Mode=GPIO_MODE_AF_PP;

GPIO_Initure.Pull=GPIO_PULLUP;

GPIO_Initure.Speed=GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(GPIOA,&GPIO_Initure);

HAL_NVIC_SetPriority(TIM2_IRQn, 2, 2);

HAL_NVIC_EnableIRQ(TIM2_IRQn);

}

}

3.3.2 加減速算法初始化

輸入?yún)?shù)是總步數(shù)、加減速時(shí)間ms、最大速度mm/s

__IO uint16_t tim_count; /* 達(dá)到最大速度時(shí)的步數(shù)*/

__IO uint32_t max_s_lim; /* 必須要開(kāi)始減速的步數(shù)(如果加速?zèng)]有達(dá)到最大速度)*/

__IO uint32_t accel_lim;

if(g_motion_sta != STOP) /* 只允許步進(jìn)電機(jī)在停止的時(shí)候才繼續(xù)*/

return;

__IO int32_t accel = (speed*1000)/accel_time_ms;

__IO int32_t decel = accel;

if(step < 0) /* 步數(shù)為負(fù)數(shù) */

{

g_srd.dir = CCW; /* 逆時(shí)針?lè)较蛐D(zhuǎn) */

step = -step; /* 獲取步數(shù)絕對(duì)值 */

}

else

{

g_srd.dir = CW; /* 順時(shí)針?lè)较蛐D(zhuǎn) */

}

if(step == 1)

{

g_srd.accel_count = -1;

g_srd.run_state = DECEL;

g_srd.step_delay = 1000;

}

else if(step != 0) /* 如果目標(biāo)運(yùn)動(dòng)步數(shù)不為0*/

{

g_srd.min_delay = (int32_t)(A_T_x10 /speed); //勻速運(yùn)行時(shí)的計(jì)數(shù)值

g_srd.step_delay = (int32_t)((T1_FREQ_148 * sqrt(A_SQ / accel))/10); /* c0 */

max_s_lim = (uint32_t)(speed*speed / (A_x200*accel/10));/* 計(jì)算多少步之后達(dá)到最大速度的限制 max_s_lim = speed^2 / (2*alpha*accel) */

if(max_s_lim == 0) /* 如果達(dá)到最大速度小于0.5步,我們將四舍五入為0,但實(shí)際我們必須移動(dòng)至少一步才能達(dá)到想要的速度 */

{

max_s_lim = 1;

}

accel_lim = (uint32_t)(step*decel/(accel+decel)); /* 這里不限制最大速度 計(jì)算多少步之后我們必須開(kāi)始減速 n1 = (n1+n2)decel / (accel + decel) */

if(accel_lim == 0) /* 不足一步 按一步處理*/

{

accel_lim = 1;

}

if(accel_lim <= max_s_lim) /* 加速階段到不了最大速度就得減速。。。使用限制條件我們可以計(jì)算出減速階段步數(shù) */

{

g_srd.decel_val = accel_lim - step; /* 減速段的步數(shù) */

}

else

{

g_srd.decel_val = -(max_s_lim*accel/decel); /* 減速段的步數(shù) */

}

if(g_srd.decel_val == 0) /* 不足一步 按一步處理 */

{

g_srd.decel_val = -1;

}

g_srd.decel_start = step + g_srd.decel_val; /* 計(jì)算開(kāi)始減速時(shí)的步數(shù) */

if(g_srd.step_delay <= g_srd.min_delay) /* 如果一開(kāi)始c0的速度比勻速段速度還大,就不需要進(jìn)行加速運(yùn)動(dòng),直接進(jìn)入勻速 */

{

g_srd.step_delay = g_srd.min_delay;

g_srd.run_state = RUN;

}

else

{

g_srd.run_state = ACCEL;

}

g_srd.accel_count = 0; /* 復(fù)位加減速計(jì)數(shù)值 */

}

g_motion_sta = 1; /* 電機(jī)為運(yùn)動(dòng)狀態(tài) */

tim_count=__HAL_TIM_GET_COUNTER(&htimx_STEPMOTOR);

__HAL_TIM_SET_COMPARE(&htimx_STEPMOTOR,STEPMOTOR_TIM_CHANNELn,tim_count+g_srd.step_delay/2); /* 設(shè)置定時(shí)器比較值 */

3.3.4 中斷處理

void TIM2_IRQHandler(void)

{

HAL_TIM_IRQHandler(&htim2);

}

void HAL_TIM_OC_DelayElapsedCallbackstepper_ctl_t *p_ctl,(TIM_HandleTypeDef *htim)

{

__IO static uint8_t i = 0;

uint32_t capture = 0;

if(htim==p_ctl->htim)

{

capture = tmr_channel_value_get(p_ctl->tmr_x, p_ctl->timer_channel);

tmr_channel_value_set(p_ctl->tmr_x, p_ctl->timer_channel, capture + p_ctl->step_delay/2);

if (STOP_MONITOR_LEVEL == rt_pin_read(STOP_PIN))

{

stepper_ctl_stop(p_ctl);

}

i++;

if (i == 2)

{

i = 0;

if (IRON_ACTION_RUN == p_ctl->action_type)

{

switch(p_ctl->run_state)

{

case STOP:

{

stepper_ctl_stop(p_ctl);

p_ctl->step_count = 0;

p_ctl->rest_delay = 0;

p_ctl->last_accel_delay = 0;

p_ctl->new_step_delay = 0;

i = 0;

}

break;

case ACCEL:

{

p_ctl->step_count++;

if (p_ctl->dir == CW)

{

p_ctl->step_position++;

}

else

{

p_ctl->step_position--;

}

p_ctl->accel_count++;

p_ctl->new_step_delay = p_ctl->step_delay - (((2 *p_ctl->step_delay) + p_ctl->rest_delay)/(4 * p_ctl->accel_count + 1));

p_ctl->rest_delay = ((2 * p_ctl->step_delay)+p_ctl->rest_delay)%(4 * p_ctl->accel_count + 1);

if (p_ctl->step_count >= p_ctl->decel_start)

{

p_ctl->accel_count = p_ctl->decel_val;

p_ctl->run_state = DECEL;

get_acc_real=p_ctl->step_count;

}

else if (p_ctl->new_step_delay <= p_ctl->min_delay)

{

p_ctl->last_accel_delay = p_ctl->new_step_delay;

p_ctl->new_step_delay = p_ctl->min_delay;

p_ctl->rest_delay = 0;

p_ctl->run_state = RUN;

get_acc_real=p_ctl->step_count;

}

}

break;

case RUN:

{

p_ctl->step_count++;

if (p_ctl->dir == CW)

{

p_ctl->step_position++;

}

else

{

p_ctl->step_position--;

}

p_ctl->new_step_delay = p_ctl->min_delay;

if (p_ctl->step_count >= p_ctl->decel_start)

{

p_ctl->accel_count = p_ctl->decel_val;

p_ctl->new_step_delay = p_ctl->last_accel_delay;

p_ctl->run_state = DECEL;

}

}

break;

case DECEL:

{

p_ctl->step_count++;

if (p_ctl->dir == CW)

{

p_ctl->step_position++;

}

else

{

p_ctl->step_position--;

}

p_ctl->accel_count++;

p_ctl->new_step_delay = p_ctl->step_delay - (((2 * p_ctl->step_delay) + p_ctl->rest_delay)/(4 * p_ctl->accel_count + 1));

p_ctl->rest_delay = ((2 * p_ctl->step_delay)+p_ctl->rest_delay)%(4 * p_ctl->accel_count + 1);

if (p_ctl->accel_count >= 0)

{

p_ctl->run_state = STOP;

}

}

break;

default:

{

}

break;

}

p_ctl->step_delay = p_ctl->new_step_delay;

}

else if (IRON_ACTION_MANUAL == p_ctl->action_type)

{

p_ctl->step_count++;

if (p_ctl->step_count >= p_ctl->manual_limit_steps)

{

stepper_ctl_stop(p_ctl);

p_ctl->step_count = 0;

}

}

else if (IRON_ACTION_RESET == p_ctl->action_type)

{

p_ctl->step_count++;

if (p_ctl->step_count >= p_ctl->manual_limit_steps)

{

stepper_ctl_stop(p_ctl);

p_ctl->step_count = 0;

}

if (ZERO_MONITOR_LEVEL == rt_pin_read(ZERO_PIN))

{

stepper_ctl_stop(p_ctl);

}

}

}

}

}

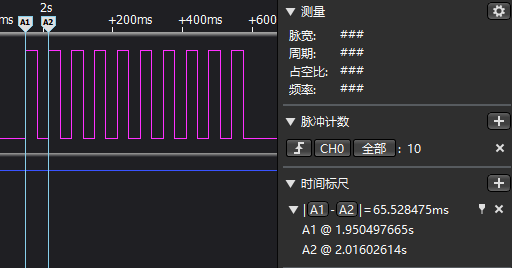

3.3.5 測(cè)試

3.3.5.1 測(cè)試生成指定脈沖個(gè)數(shù)

生成10個(gè)脈沖,脈沖寬度為1*0xFFFF/1000000=0.065535S

#define MAX_TIMER_CNT 0xFFFF

TIM_PWM_Init(MAX_TIMER_CNT,TIM_PRESCALER);

uint32_t set_cnt_pwm = 10;

uint32_t get_acc_real = 0;

uint32_t set_cnt_pwm = 10;

void HAL_TIM_OC_DelayElapsedCallback(TIM_HandleTypeDef *htim)

{

__IO uint32_t tim_count = 0;

__IO uint32_t tmp = 0;

__IO static uint8_t i = 0;

if(htim->Instance==TIM2)

{

tim_count = __HAL_TIM_GET_COUNTER(&htimx_STEPMOTOR);

tmp = tim_count + MAX_TIMER_CNT/2;

__HAL_TIM_SET_COMPARE(&htimx_STEPMOTOR,STEPMOTOR_TIM_CHANNELn,tmp);

i++;

if(i == 2)

{

i = 0;

if(i == 2)

{

i = 0;

set_cnt_pwm--;

if (0 == set_cnt_pwm)

{

set_cnt_pwm = 10;

HAL_TIM_OC_Stop_IT(&htim2,TIM_CHANNEL_2);

}

}

}

}

}

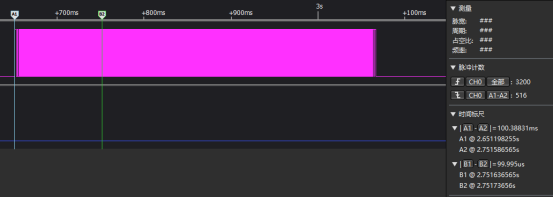

實(shí)測(cè)波形

3.3.5.2 測(cè)試設(shè)置指定參數(shù)

如果一圈的脈沖數(shù)是1600,位移是5*3.14159mm,那么100mm/s就需要10185.9個(gè)脈沖每秒,1000000/10186,那么最大速度時(shí)的計(jì)數(shù)為98,脈沖周期也就是98us左右

#define CONFIG_SPEED_MMPS 100

#define MMPS_TO_RAD_0_1_PS(SPEED) ((SPEED*2*3.14159*10)/5*3.14159)

float set_speed = MMPS_TO_RAD_0_1_PS(CONFIG_SPEED_MMPS);

create_t_ctrl_param(CONFIG_STEPS_PER_ROUND*2, 100, set_speed);

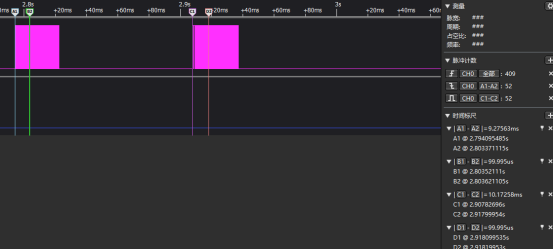

實(shí)測(cè)波形

A1-A2的時(shí)間剛好是100ms,脈沖個(gè)數(shù)是516個(gè),這個(gè)加速階段的步數(shù)比理論值要大,

脈沖周期是100us左右,比理論上要大2us。

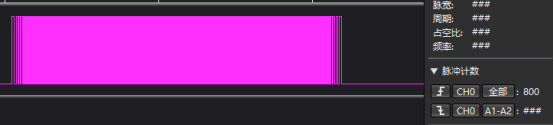

3.3.5.3 測(cè)試執(zhí)行連續(xù)的動(dòng)作

假設(shè)需要完成2個(gè)動(dòng)作,每一次的距離是2mm,間隔是200ms,2mm對(duì)應(yīng)的步數(shù)=204

#define ROUND_UP_CNT_GAIN_100 (50)

#define ROUND_UP(M,N) ((((M*100)/N)+ROUND_UP_CNT_GAIN_100)/100)

#define CONFIG_STEPS_PER_ROUND (1600)

uint32_t distance_to_steps_mm_gain(uint32_t set_mm_gain, uint32_t set_gain)

{

uint32_t set_gain_val = CONFIG_ROUND_MM*set_gain;

return ROUND_UP(set_mm_gain*CONFIG_STEPS_PER_ROUND,set_gain_val);

}

create_t_ctrl_param(distance_to_steps_mm_gain(200,100), 10, set_speed);

HAL_TIM_OC_Start_IT(&htim2,TIM_CHANNEL_2);

while (g_motion_sta)

{

}

delay_ms(200);

create_t_ctrl_param(distance_to_steps_mm_gain(200,100), 10, set_speed);

HAL_TIM_OC_Start_IT(&htim2,TIM_CHANNEL_2);

實(shí)測(cè)波形

4 實(shí)測(cè)效果

正向轉(zhuǎn)4次,每次1圈,速度是10mm/s,反向轉(zhuǎn)1次,轉(zhuǎn)1圈,速度是2mm/s

-

算法

+關(guān)注

關(guān)注

23文章

4607瀏覽量

92840 -

步進(jìn)電機(jī)

+關(guān)注

關(guān)注

150文章

3109瀏覽量

147443 -

定時(shí)器

+關(guān)注

關(guān)注

23文章

3246瀏覽量

114720 -

加減速算法

+關(guān)注

關(guān)注

0文章

7瀏覽量

7161 -

驅(qū)動(dòng)方式

+關(guān)注

關(guān)注

0文章

15瀏覽量

7387

發(fā)布評(píng)論請(qǐng)先 登錄

相關(guān)推薦

STM32:F407步進(jìn)電機(jī)S形加減速算法的實(shí)現(xiàn)相關(guān)資料分享

啟動(dòng)停止頻繁步進(jìn)電機(jī)加減速算法目的是什么

步進(jìn)電機(jī)驅(qū)動(dòng)算法——S形加減速算法原理 精選資料下載

F407步進(jìn)電機(jī)梯形加減速算法是如何實(shí)現(xiàn)的?

步進(jìn)電機(jī)梯形勻加速算法是什么

淺析步進(jìn)電機(jī)S型曲線加減速算法

怎么實(shí)現(xiàn)STM32步進(jìn)電機(jī)S型加減速算法?

梯形加減速算法實(shí)現(xiàn)

梯形加減速的相關(guān)資料推薦

步進(jìn)電機(jī)S加減速算法與查表方式哪個(gè)更好?

STM32 多步進(jìn)電機(jī)加減速算法精確控制 親測(cè)可用~~~

步進(jìn)電機(jī)驅(qū)動(dòng)算法之梯形加減速算法

步進(jìn)電機(jī)的基本參數(shù)及梯形加減速算法

步進(jìn)電機(jī)的基本參數(shù)及梯形加減速算法

評(píng)論