粉末電阻測試概述Overview of Powder Testing

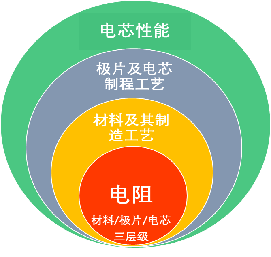

材料電阻直接影響著全電池功率表現。通過測量分析粉末、極片電阻等特性,在快速預測電池性能方面具有重要意義。 Resistivity of material directly affects the power performance of full battery. It is very important to predict the battery performance quickly by measuring and analyzing the characteristics of powder and electrode resistivity . 粉末導電材料的電阻率與材料本體電阻特性、粒度直接相關外,還與粉體堆積松緊度等直接關聯。The resistivity of powder is not only directly related to the resistance characteristics and particle size of conductive material itself, but also directly related to the tightness of powder accumulation.

當前測量瓶頸Current situation and difficulties

粉末電阻的測試有多種方法,其中四探針是常用的方法之一。不過,四探針法仍存在如下問題亟需解決,以便方便高效地進行粉體電阻及壓實密度的測試。Four probes is one of the commonly used methods for powder resistivity. However, the following problems need to be solved in order to facilitate and efficiently test powder resistance and press density.

非原位(需預壓片,再轉移至設備上測試),測試過程繁雜,影響因素眾多;Ex-situ test(requires prepressing, then transferring it to the equipment for testing). The testing process is complicated and there are many influencing factors.

沒有粉末電阻與壓實密度一體設備;No powder resistivity and press density integrated equipment;

無法實現不同壓力下粉末電阻與壓實密度同步測試; The synchronous test of powder resistivity and press density under different pressures cannot be realized;

無法實現大壓力下粉末電阻與壓實密度測試 ;The test of powder resistivity and press density under high pressures cannot be realized.

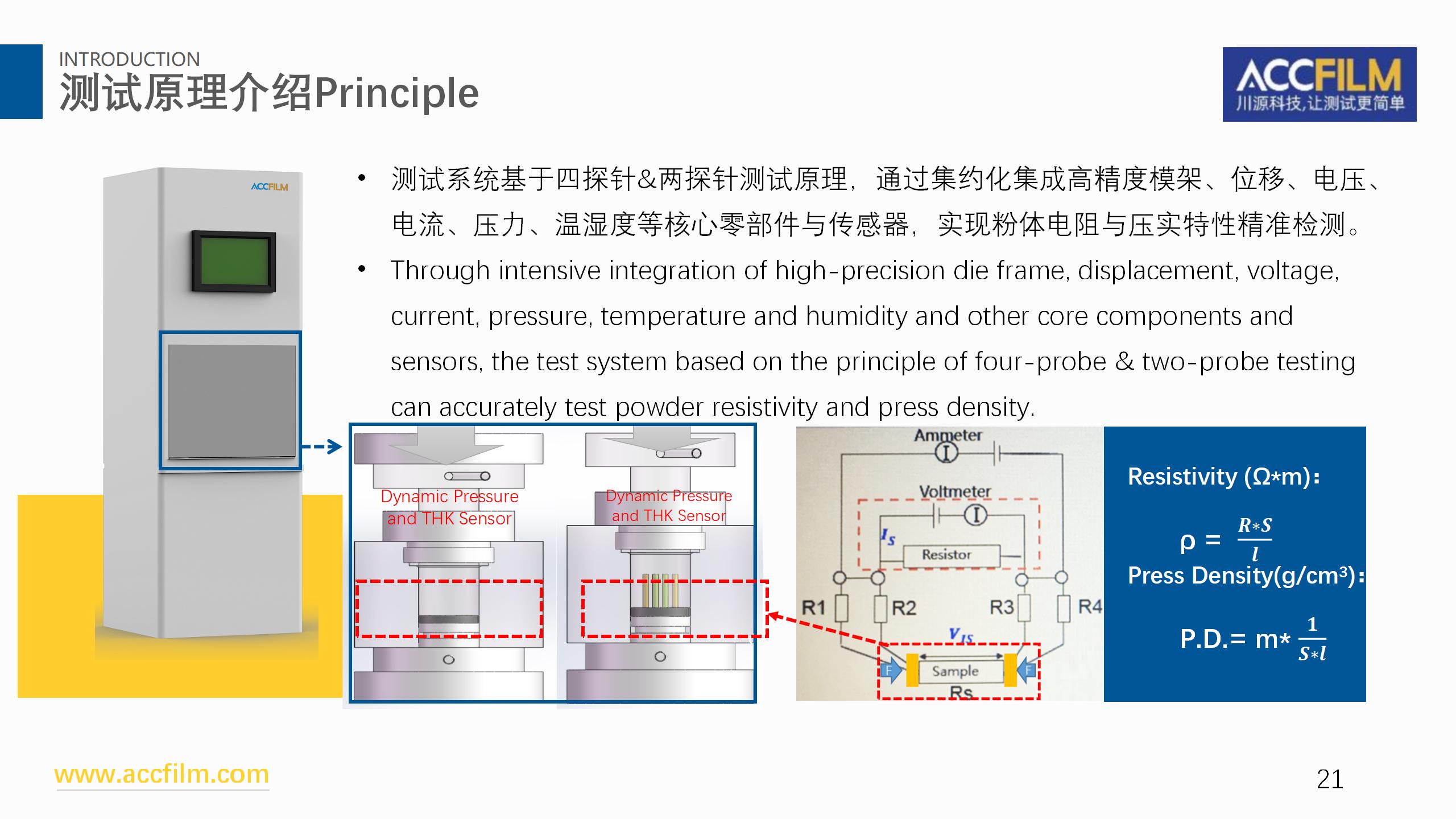

測試原理介紹Principle

測試系統基于四探針&兩探針測試原理,通過集約化集成高精度模架、位移、電壓、電流、壓力、溫濕度等核心零部件與傳感器,實現粉體電阻與壓實特性精準檢測。

Through intensive integration of high-precision die frame, displacement, voltage, current, pressure, temperature and humidity and other core components and sensors, the test system based on the principle of four-probe & two-probe testing can accurately test powder resistivity and press density.

測量模式介紹Test Mode

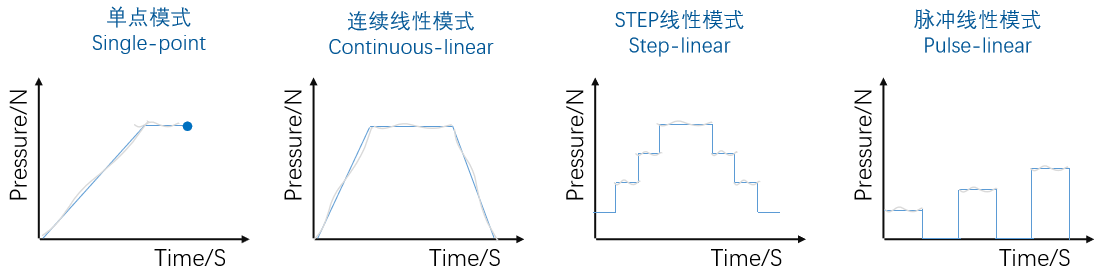

測試系統實現以下功能 (類似電池充放電,CC+CV模式,Step Charge 模式); Test system realize the following function(similar to cell test, CC+CV mode,Step Charge mode):

不同加載壓力速率到目標壓力,目標壓力保持一定時間, 直到電阻變化率小于0.01mΩ/s,完成測試;

For example :0.1t/s Constant Force rate(CFR) to 0.3t, Constant Force(CF) to 0.01mΩ/s, Frequency 0.2S。

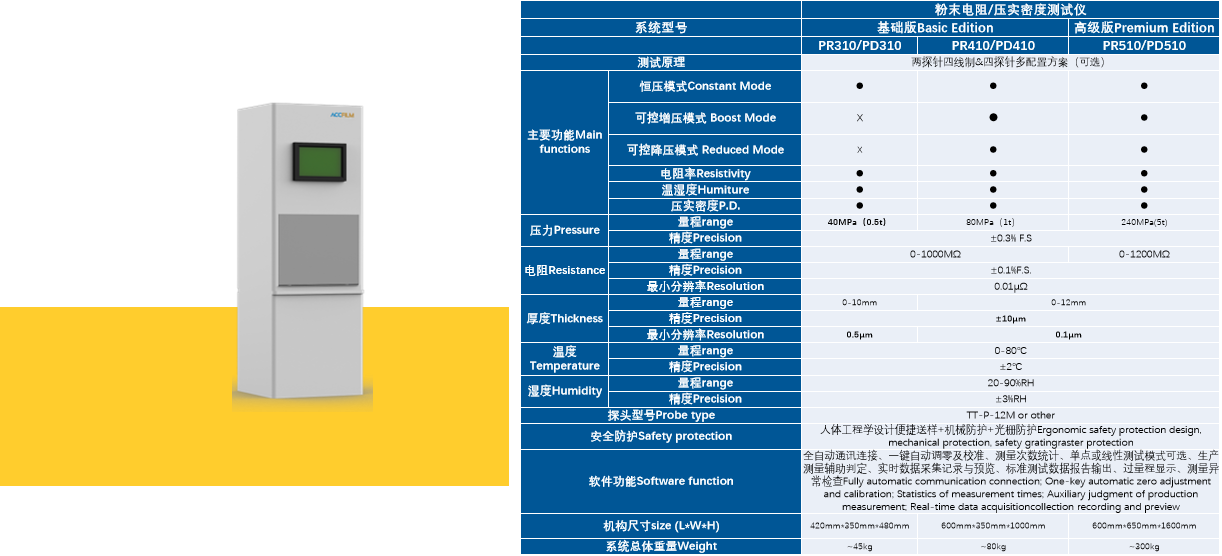

系統參數Specifications

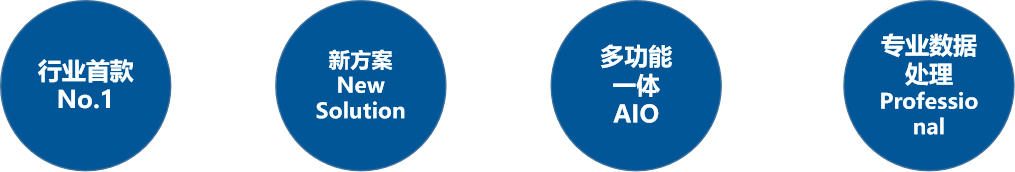

產品特色與優勢Features and Advantages

可靠性分析Reliability Analysis

測試系統采用的是可控壓力加壓的測試來保證接觸一致性,從而確保了測量的可靠性及穩定性,設備測試結果可靠,并且能達到量具R&R的標準要求。Test system adopt the controllable pressurize test to guarantee the contact uniformity, reliability and stability of test.

R&R可區分的類別數為9.35;The number of distinguishable R & R categories is 9.35;

方差分量貢獻率及研究變異值大小同樣顯示系統的可靠性良好;%SV and 6*SD also display the better system reliability;

應用領域與方向Application Fields

ACCFILM膜片電阻測試系統應用于鋰電池、超級電容器及鎳氫電池等二次電池材料研發與生產相關領域的生產制造企業、大學及科研院所,其主要輸出測量測試如下:

Manufacturing enterprises, universities and research institutes of lithium battery, supercapacitor and other secondary battery material related fields;

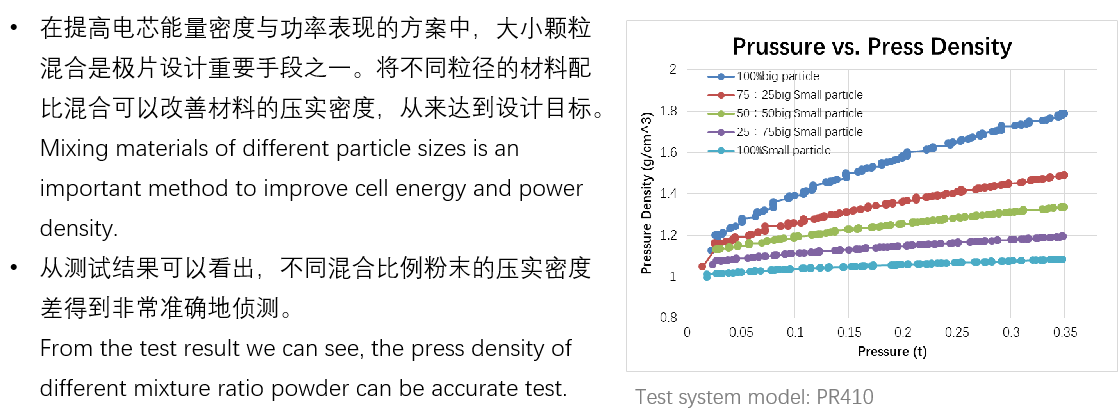

石墨混合壓實密度分析Mixed Graphite Density Analyse

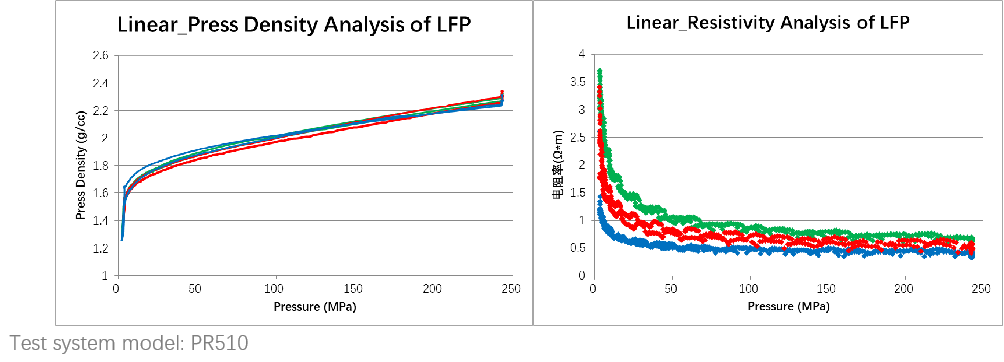

不同LFP材料測試分析Different LFP Material Analysis

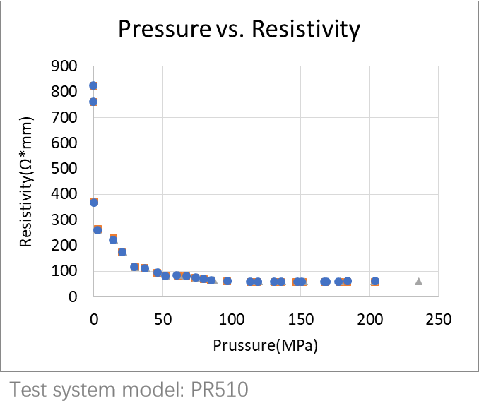

為了研究更高壓施壓狀態下粉體特性,以下為240MPa下三款LFP粉體的電導性及壓實密度特性參數; To research powder characteristics under more higher pressure loading status, the below are resistivity and press density parameters of LFP powder under 240MPa; 三款材料中高能量型、能量型及倍率型的電阻率依次降低;The resistivity characteristics of three types materials match with the particle size design.

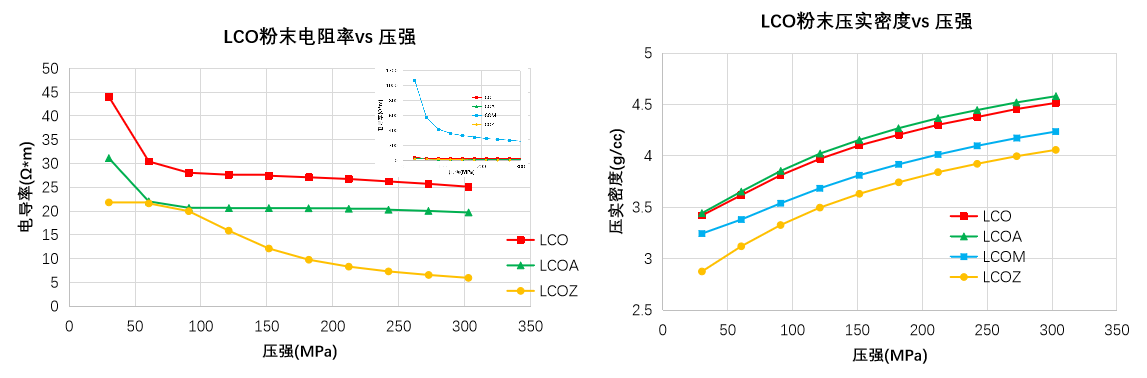

不同包覆改性LCO分析Doping LCO Analysis

300MPa下,LCOZ粉末電阻率最小5.946Ω*m,電阻從小到大依次為LCOZ<LCOA<LCO<LCOM,其中LCOM的組別實驗組效果最差;

300MPa下,LCOA粉末壓實密度最大達到4.58g/cc,壓實密度從小到大依次為LCOZ<LCOM<LCO<LCOA;

壓實密度和壓力的關系趨勢一致;

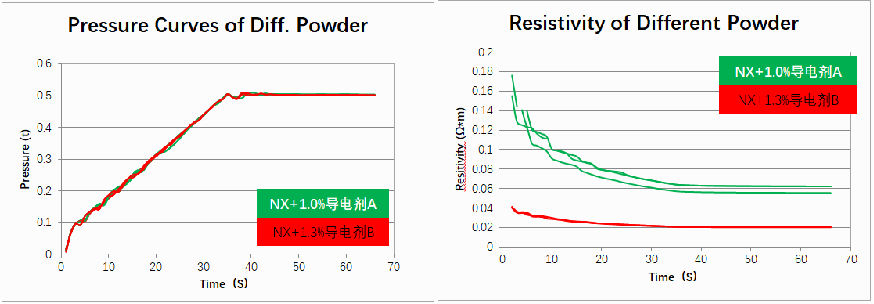

鈉電池正極電阻分析 Na-ion Cell Cathode Materials Analyse

針對鈉離子電池正極材料的材料導電性進行測試分析,以下為一款聚陰離子正極粉體(NX系列)混合兩種不同導電添加劑的電導性評估. The below is the resistivity of polyanionic-based cathode materials (NX series) mixed two conductive additives:

NX+1.3%導電劑B的整體電導性比NX+1%導電劑A的效果好很多;The whole resistivity of NX+1.3%B more better than NX+1% A;

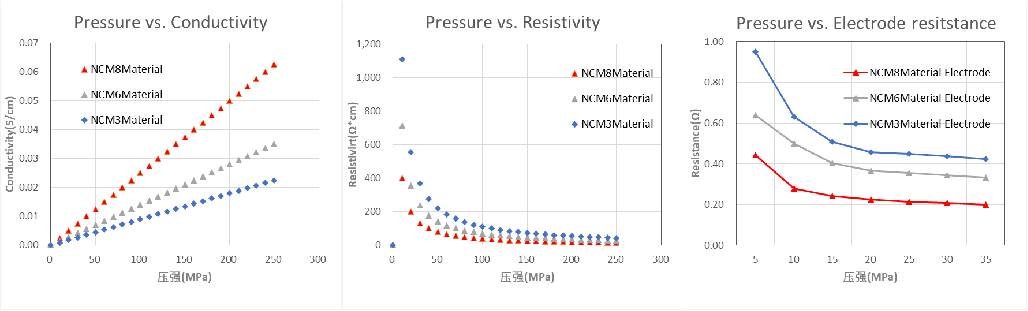

三元材料電阻率評估NCM Resistivity Analysis

針對不同三元材料的電導性測試應用,粉末電阻測試系統能有效地區分不同材料電阻率;Test system able to measure different type NCM material resistivity;

另外,可以看出粉末電阻率與極片電阻呈相同變化趨勢。Additionally, we can see that resistivity and electrode resistance shows the same trend.

石墨粉料生產穩定性評估Stability of Graphite production

為了提高電池的一致性與可靠性,傳統克容量、顆粒度、BET等檢測已經不足以保證材料的一致性。所以,對于評價材料一致性非常有用的粉末電阻率就變得越來越重要。In order to improve the consistency and reliability of the battery, the traditional specific capacity, particle size, BET and other tests are not enough to ensure the consistency of the material. Therefore, powderresistivity test becomes more and more important.

右圖展現了不同生產批次石墨粉料的電阻數據,用于材料生產穩定性監控。 The picture show the resistivity data of different graphite batches, which is used to monitor the stability of material production.

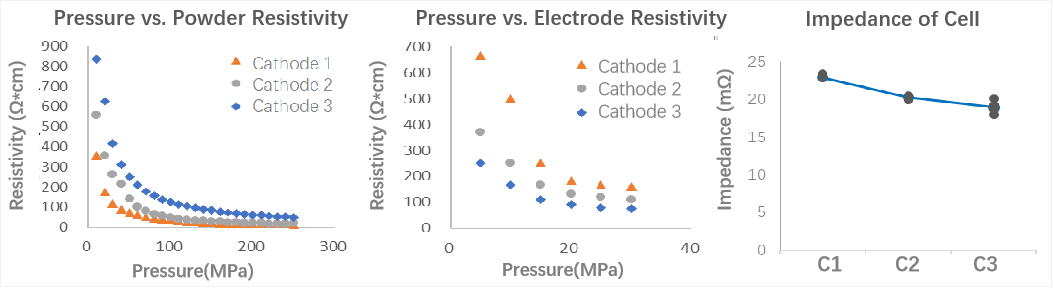

粉末、極片與電芯電阻關聯分析Correlation analysis of powder, electrode and Cell

為了加快電池研發效率,希望通過零部件的性能來預測電芯性能,比如:利用粉末電阻、極片電阻來預測電芯內阻、功率等表現;By analyzing the resistance components of different levels(Such as powder, electrode ) to predict the performance of full cell.

以下示例為NCM811材料在不同導電添加劑量下粉末、極片及電芯內阻的對應結果。The corresponding results of powder, electrode and cell resistance of NCM811 with different conductive additive.

審核編輯黃宇

-

電阻

+關注

關注

86文章

5507瀏覽量

171931 -

測試

+關注

關注

8文章

5269瀏覽量

126599 -

電池

+關注

關注

84文章

10560瀏覽量

129480

發布評論請先 登錄

相關推薦

IGBT飽和壓降Vsat實測值和官方參數對比

【QR-10系列通用型袖珍可編程電阻箱試用體驗】---之電阻數據實測

Maxim推出堅固耐用的/PR系列塑封器件,適合軍用和航空設

Vishay發布ORNV系列模壓雙列直插電阻分壓器

什么是電阻分壓?電阻分壓的工作原理是什么?電阻分壓和限流是一個概念嗎?

接地電阻測試記錄表_接地電阻測試記錄_萬用表怎么測接地電阻

粉末電阻/壓實測試(PR系列)

粉末電阻/壓實測試(PR系列)

評論